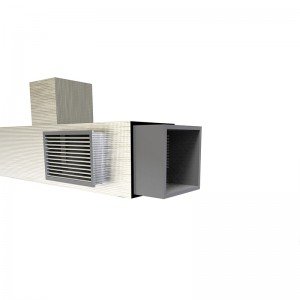

ESD turnover box

ESD turnover box

SHORT DESCRIPTION:

Feature

Conductive foam has good conductivity. The resistance of conductive foam is 10^3-10^6.

Conductive foam and anti-static foam has following features:

heat insulated

sound insulated

free of chemical corrosion

no corrosion to components and packaging

good secondary processing performance

easy to form and compressive

Good wear resistance

excellent cushioning and shock absorption performance

independent and fine closed cells

IXPE conductive/antistatic foam:

This product is made by extruding polyethylene or modified polyethylene, conductive fillers and antistatic agents, through radiation crosslinking, and high temperature foaming to make conductive/antistatic foam. Its surface The resistance and volume resistance are 10^3-9 Ω. It is characterized by permanent conductivity/anti-static, conductivity/anti-static performance is not affected by environmental humidity, smooth surface, environmental protection, easy to secondary molding processing, widely used in LCD screen production and assembly Line mobile phones, 3G terminals, computers/especially notebook computers, optoelectronic components, PCB board workshop turnover and electronic products that are prone to static electricity during transportation. Anti-static foam is similar to a very large resistance, with extremely weak conductivity, theoretically tearing strength is better than conductive foam.

The resistance value of anti-static foam and conductive foam has a range:

10^3 to 10^6 conductive

10^3 to 10^9 anti-static

Due to the difference in resistance value, the static half-life of conductive foam is shorter than that of anti-static foam, and the static voltage of conductive foam is also much smaller than that of anti-static; but both can automatically release charges. Anti-static foam is to disperse the electric potential generated during product handling into the foam and further reduce the electrostatic hazard. According to the breakdown voltage of different products and the working environment, the charge dissipation of anti-static foam is slower and more suitable for precision small strokes. For electronic products with high breakdown voltage, conductive foam has a faster charge dissipation, which is suitable for high breakdown voltage or needs to dissipate the charge faster.