Closed cell and crosslinked pe foam for thermal insulation

Closed-cell-and-crosslinked-pe-foam-for-thermal-insulation

Closed-cell-and-crosslinked-pe-foam-for-thermal-insulation

Closed cell and crosslinked pe foam for thermal insulation

SHORT DESCRIPTION:

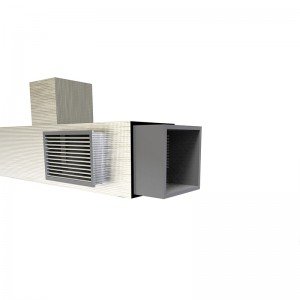

XPE or IXPE double sides laminated with aluminum foil, with advanced thermal performance reflecting up to 95% radiant heat, allowing for cooler internal conditions in hot and climates also it has great property of flame retardant, which pass Class 0 (BS476 6&7). Closed cell and crosslinked pe foam is excellent for buildings insulation, like sheds, workshops factories etc.

| Dimension | 4mm * 1350mm * 40mts (or customized) |

| Density | 30~36kg/m3 (or customized) |

| Usage | Roof / wall / floor |

| Structure |

Aluminum foil + XPE foam + adhesive Aluminum foil + XPE foam + aluminum foil Aluminum foil + IXPE foam + adhesive Aluminum foil + IXPE + aluminum foil (or customized) |

| Color | Black / gray / pantone color |

| Service life | More than 30 years |

Properties

1.Moisture barrier water-proof, heat insulation energy saving

2. Light, soft, dust-free, flame retardant, easy cutting and installing

3. No odor, environmentally-friend

4. Low thermal conductivity and excellent heat insulation s& thermal insulation

5. Keep warmer in winter, cooler in summer.

Data sheet

| Property | Standard | Unit | Value | |

| Density | – | Kg/m3 | 33 | |

| Tensile strength | Transverse | ISO- 1798 | Mpa | 0.25~0.27 |

| Longitudinal | 0.31~0.32 | |||

| Elongation | Transverse | ISO- 1798 | % | 137.40~141.20 |

| Longitudinal | 159.70~166.00 | |||

| Tearing strength | Transverse | ISO- 8067 | Kn/m | 1.28~1.33 |

| Longitudinal | 1.38~1.40 | |||

| Compression 25% | ISO- 3386-1 | Kpa | 36.40 | |

| Compression 40% | ISO- 3386-1 | Kpa | 62.40 | |

| Compression 50% | ISO- 3386-1 | Kpa | 95.20 | |

| Compression set 25% 0.5H | ISO- 1856 | % | 19.10 | |

| Compression set 25% 24H | ISO- 1856 | % | 4.10 | |

| Operating Temperature range | Internal | ℃ | (-40, +80) | |

| Water absorption % volume (max) | Internal | % | 0.50 | |

| Thermal conductivity | JIS A1412-2 | w/mK | 0.038 | |

| Shore-C Hardness | ASTM D2240 | ℃ | 22 | |

Note: this TDS is for your reference only based on the date of a sample test, and it not stands for all batches’ property. So, there may differ in different production.

If you want to know more details, please contact us via e-mail: info@meishuocopy.com.

Leave Your Message

FIll out the form below and we will cantact you as soon as possible